The most common cause of torch damage

(1) Torch collision.

(2) A destructive plasma arc due to damage to the consumables.

(3) Destructive plasma arc caused by dirt.

(4) Destructive plasma arc caused by loose parts.

Features

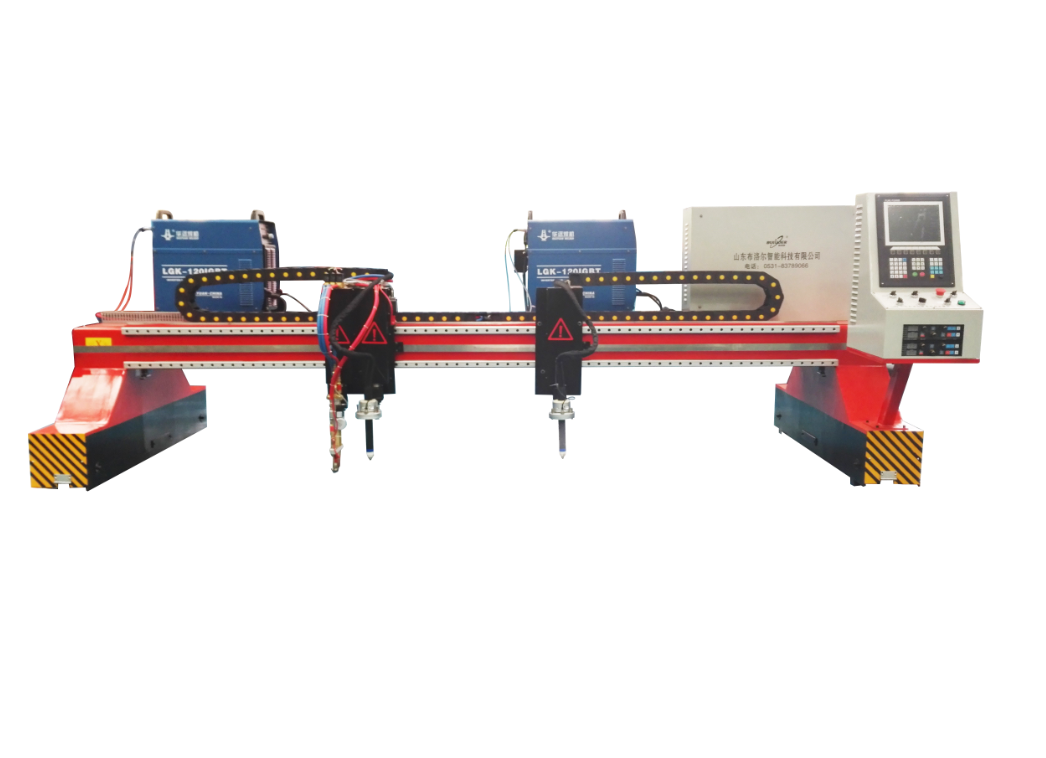

Double gun operation reduces labor costs by 50%.

Transportation and material costs are reduced by 10%.

High processing efficiency, 2.2 times that of single shot cutting.

Optional capacitor or plasma automatic height adjustment system to effectively avoid plate deformation wave deformation collision.

Imported electrical appliances, stable performance, anti-interference and long life.

Servo drive, high control precision, stable moment frequency characteristics, strong overload capability and fast response.

The numerical control and drive adopt modular integrated design, and the buttons and the chassis are completely shielded from all steel structures, preventing electromagnetic radiation and anti-static.

Advantages: high efficiency and accuracy, high stable cutting quality

Scope of application: carbon steel, galvanized sheet, stainless, aluminium plate, copper plate, manganese plate and metal sheet materials.

The essence of the working process of the plasma device is as follows: An arc is generated between the inner nozzle (anode) of the gun and the electrode (cathode), so that the moisture between them is ionized to reach the state of the plasma. At this time, the ionized vapor is ejected into the nozzle in the form of a plasma jet by the pressure generated internally, and the temperature is about 8 000 ° C. This cuts, welds, welds and other forms of heat treatment of non-combustible materials.