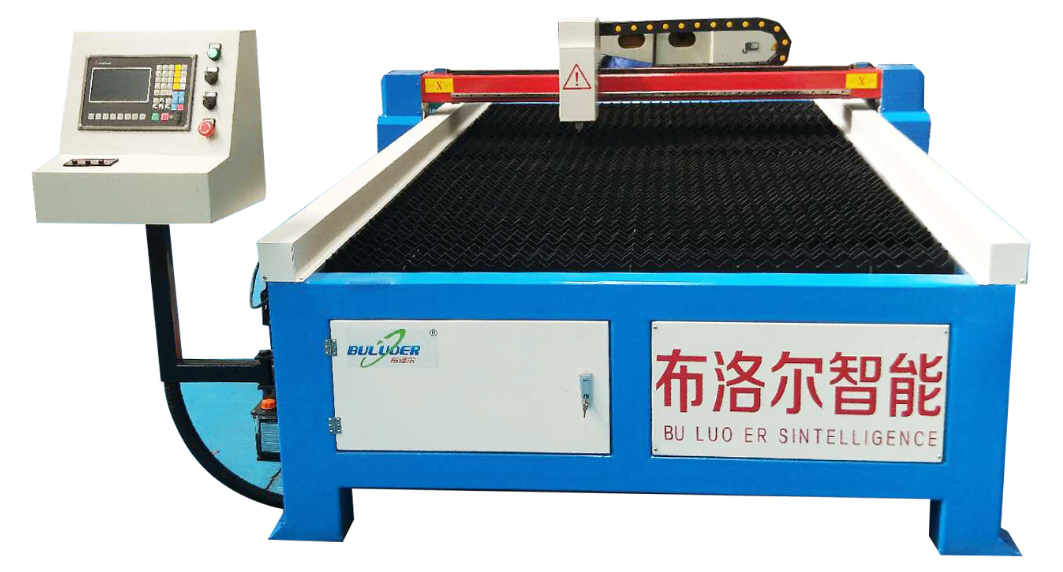

In terms of cutting accuracy, because it is a roughing equipment, its machining accuracy is generally about 1mm.The beam is made of aluminum alloy, which is light in weight and has little inertia during operation. It is more flexible to start and stop, making walking more precise and ensuring cutting quality.

Both the X and Y axes are driven by the most sophisticated rack and pinion in the country, and the walking accuracy can be ensured without the need of a backlash.

It adopts the well-received Star Peak CNC system, which is powerful, easy to operate, easy for operators to train, and has a high penetration rate. It is no longer necessary to worry about buying equipment that no one can operate.

Features

1. Built-in cooling and exhausting environmental protection system.

2. Fully automatic oil lubrication, low noise and maintenance free.

3. 600 ° C high temperature tempering treatment of the rack and the whole processing is not deformed.

4. Bilateral drive, stable operation, high cutting precision and fast speed.

5. Original imported motor, reducer, high precision gears, racks, guides.

Advantages: Bilateral dual signal synchronous drive, high stability and long service life

Scope of application: carbon steel, low alloy steel, stainless, aluminium plate, aluminium alloy, copper plate, copper alloy and metal sheet materials.

The drive system is servo drive or stepper drive. It can be driven by imported Japanese Panasonic AC servo drive or stepper motor according to user's needs. It is a smoother operation of the whole machine, with wider speed range and shorter acceleration time.

This machine has a smoking dust removal device and an air-driven cutting table and slag storage device to create a good working environment.

The arc voltage height adjuster with high response sensitivity automatically adjusts the cutting distance to ensure the precision cutting of the workpiece.

According to user requirements, a variety of plasma power supplies can be selected to meet different metal material cutting.

The equipment is easy to install, easy to operate, easy to use; easy to install and relocate, suitable for the user's limited space, processing environment with small cutting width, especially suitable for cutting of medium and thin non-ferrous metal sheets, stainless steel, titanium, aluminum alloy and carbon steel sheets. material. Application areas: sheet metal processing, power equipment, agricultural machinery manufacturing, machinery manufacturing, aerospace, vehicle manufacturing.

Processing precision and stability beyond imagination

Due to the use of a dedicated servo technology platform, its processing accuracy and stability are greatly improved. In addition to being equipped with a common plasma power supply, it can also match the fine plasma power supply to achieve laser-like cutting levels. The only whole process test in China, with its own research center and testing laboratory, to ensure the source control and process control of the products, the key components have not been repaired in the past 10 years.