The CNC Flame Cutting Machine can use three main air sources. 1. Industrial acetylene: Acetylene is also called calcium carbide gas, and its quality is lighter than oxygen. It is colorless at normal temperature and pressure. It is a dangerous explosive gas. When the temperature exceeds 200-300 degrees, acetylene will undergo an exothermic polymerization, and the heat will be released and further polymerized. If the heat cannot be quickly eliminated during this process, the increase and acceleration of the polymerization will increase the temperature of the acetylene, resulting in a hazard. Industrial acetylene, which contains a large amount of impurities, such as hydrogen sulfide, phosphine, etc., has a strong pungent odor. Acetylene has the highest solubility in acetone, and bottled acetylene is stored and transported by its solubility in acetone. 2. Industrial oxygen: Oxygen is a colorless, odorless gas that cannot burn itself. It is a lively combustion-supporting gas. The oxygen tank has a maximum pressure of 150 atmospheres and a volume of 40 liters. A pressure reducer is provided at the outlet of the oxygen cylinder to reduce the high pressure oxygen to the required working pressure, about 3-4 atmospheres and to stabilize the pressure.

3. Propane: a colorless, odorless gas at room temperature. Flammable, explosive, and chemically stable. Decomposed to ethylene and ethane at 650 °C. Propane is mainly found in oil gas, natural gas, and refinery gas. Mixing with air can form an explosive mixture. In case of heat and open flame, there is a danger of burning and explosive. The limit is 2.1%-9.5%. Contact with oxidant reacts violently. Density is greater than air, can spread to a relatively distant place at a lower place, and will ignite in the event of fire. Propane easily forms solid hydrates with water at low temperatures, causing blockage of the gas pipeline.

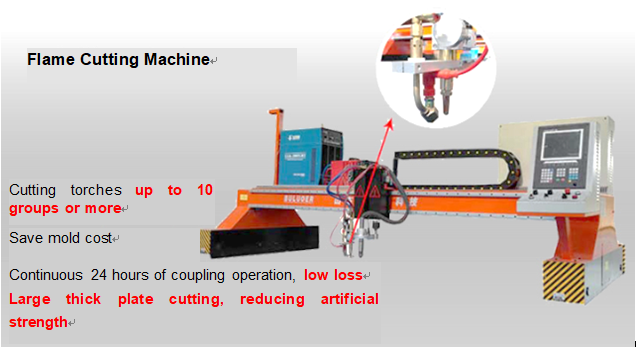

CNC flame Cutting Machine has the ability to cut carbon steel with large thickness, and the cutting cost is low, but the cutting deformation is large, the cutting precision is not high, and the cutting speed is low, the cutting preheating time and the piercing time are long, and it is difficult to adapt to the fully automated operation. Need. Its application is mainly limited to carbon steel, large thickness sheet cutting, and will be replaced by plasma cutting on medium and thin carbon steel sheet cutting.