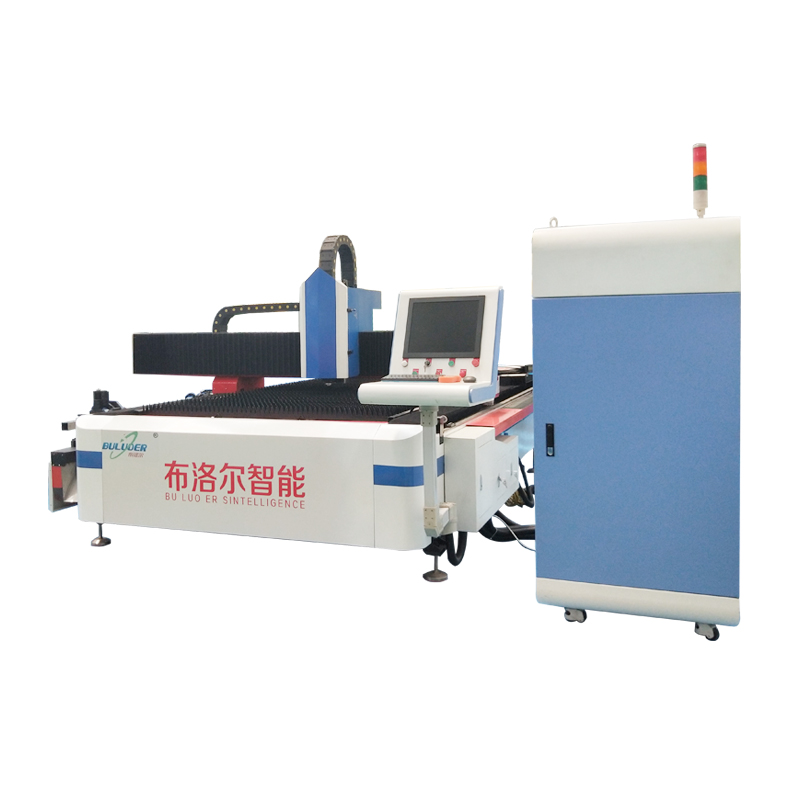

Many manufacturers of Metal Cutting Machine Laser in the processing of metal materials, in addition to the board, the pipe is also a relatively large number of materials, the following to bring you a Fiber Laser Cutting Machine, can cut the board, but also can cut the pipe, can achieve a variety of industry value cutting laser equipment.

CNC fiber Laser Cutting Machine is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickling board, galvanized sheet, copper and other metal materials.

Imported with original packaging servo motor and reducer, bilateral drive, high operating speed and high precision.

Suit material: carbon steel, alloy steel, galvanized plate, stainless steel, copper plate, aluminium plate, steel tube, copper pipe, aluminium pipe etc. sheet metal, tube stock.

Can remote operation, convenient and efficient, save labor.

Imported cutting head, optical glass, focusing is convenient and cutting perfect.

Fiber transmission, no need to adjusted the optical circuits, focal spot is more smaller.

Adopted auto lubrication system, auto dual-temperature control system, convenient and efficient.

High precision grinding guide rail, gear and rack, precision class up to ±0.02mm.

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a plurality of rectangular tubes. The inside of the tube is provided with reinforcing ribs to increase the strength and tensile strength of the bed, increase the tensile strength and stability of the guide surface, and effectively avoid deformation of the bed. .

High strength, stability, tensile strength, guarantee no deformation after 20 years of use;

The tube-and-tube integrated laser Cutting Machine is a cutting device for round tubes, square tubes, shaped tubes and planes. It has an automatic control system, which can realize high flexibility, high precision and multi-directional cutting. The individualized needs of modern industrial manufacturing and High-quality production, the traditional Pipe Cutting Machine can not meet these standards, and the plate and tube integrated laser cutting machine as a pipe and flat cutting equipment, the process and performance have increased.

Fast cutting speed, high working efficiency and high stability, it is a high-tech equipment that set one of fiber laser technology, CNC technology and high-tech equipment.

Due to the cutting of the tube tube (for the square tube plate with small diameter), the slag adheres to the inner wall of the tube, and most of the heat generated by the cutting is absorbed by the workpiece. When the cutting density is large, the tube sheet is often overheated, corners and squares. The four corners of the tube burned, which seriously affected the quality of the incision and could not even be cut. For such problems, you can use:

1 laser cutting head with high-speed sensing follow-up system can cut the nozzle and the surface of the workpiece in the process of cutting the same high (focus unchanged), so that the cutting results are not affected by the change of the surface of the workpiece

2 method of increasing oxygen pressure;

3 Increase the sharp corner synthesis speed by software.