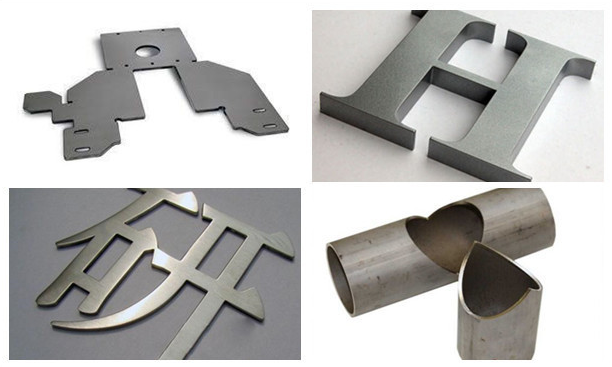

Buluoer CNC Flame Cutting Machine has various models, complete varieties, fully automatic FASTCAM graphic programming software, simple nesting, good structural rigidity, high transmission precision, bilateral drive, stable operation, and can meet the multi-dimensional needs of users. Next, let's take a look at the principle of CNC flame Cutting Machine. I. Cutting principle CNC flame cutting, also called gas cutting, is a process of burning with an oxygen gas flame. When the temperature of the cutting material rises to the ignition point, the oxygen flow oxidizes the metal in a narrow region, and the slag generated during the combustion is blown off by the cutting oxygen flow to form a slit. The CNC flame cutting machine is a mechatronic cutting device that uses a digital program to drive the machine tool movement, is equipped with a flame cutting system, uses a numerical control system to control the switch of the flame cutting system, and cuts metal materials such as steel plates.

II. Control software

The CNC flame cutting machine control software mainly includes four modules, in which the document module completes the storage and reading of the file, and the graphic input module and the processing module jointly complete the processing of the parts to realize CAD/CAM. The system setting module is responsible for setting the initialization parameters and motion parameters. At the same time, the PLC in the flame cutting CNC system realizes the valve action and timing control of the cutting gas path. In the CNC flame cutting machine system, in order to keep the distance between the cutting head and the steel plate constant, an automatic height adjustment device must be provided. The graphic information input module of the control system adopts various methods, and the main input mode is: manual input of G code mode.

III. Cutting requirements

1. The equipment is generally selected to use a neutral flame or a slight oxidizing flame. In the cutting process, the flame strength should be moderate. Before the cutting, the preheating flame should be selected according to the thickness of the workpiece, the type of cutting nozzle and the cutting requirements.

2. The fire should be carried out in the preheating state. After the feeling is adjusted, observe whether the adjusted flame is ideal. If it is not ideal, turn off the cutting oxygen and return to the preheating state and adjust it.

IV. The thickness of the cutting material

Oxygen gas cutting can be used for carbon steel and low alloy steel, and the thickness can reach several decimeters. The quality of the cut depends on the surface condition of the material, the cutting speed and the thickness of the material. Material thickness: 3mm to 2800mm; currently the thickness of the cutting machine can be achieved by ordinary flame cutting machine: 10mm to 200mm. However, the numerical control flame cutting machine is the cutting method with the largest cutting thickness among many cutting methods. Generally, if the cutting thickness is higher than the typical thickness, the number of the gas path, cutting torch, oxygen and gas of the cutting machine must be changed. If the power is not up to the requirements, the plate will not be cut.

As a large-scale CNC machine tool, subject to the cutting principle and the transmission performance of the machine tool, the running speed of the CNC flame cutting machine can't be too fast, generally within 0.1m/min. To ensure the cutting quality and effect, the recommended speed is controlled. About 700mm/min is more suitable. The transmission ratio of the machine drive train is relatively large, so the transmission rigidity of the machine drive train is significantly lower.