The basic plasma cutting process involves creating an electrical channel of superheated, electrically ionized gas i.e. plasma from the Plasma Cutter itself, through the work piece to be cut, thus forming a completed electric circuit back to the plasma cutter via a grounding clamp.

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist shops.

The basic plasma cutting process involves creating an electrical channel of superheated, electrically ionized gas i.e. plasma from the plasma cutter itself, through the work piece to be cut, thus forming a completed electric circuit back to the plasma cutter via a grounding clamp. This is accomplished by a compressed gas (oxygen, air, inert and others depending on material being cut) which is blown through a focused nozzle at high speed toward the work piece. An electrical arc is then formed within the gas, between an electrode near or integrated into the gas nozzle and the work piece itself. The electrical arc ionizes some of the gas, thereby creating an electrically conductive channel of plasma. As electricity from the cutter torch travels down this plasma it delivers sufficient heat to melt through the work piece. At the same time, much of the high velocity plasma and compressed gas blow the hot molten metal away, thereby separating, i.e. cutting through, the work piece.

Plasma cutting is an effective way of cutting thin and thick materials alike. Hand-held torches can usually cut up to 38 mm (1.5 in) thick steel plate, and stronger computer-controlled torches can cut steel up to 150 mm (6 in) thick. Since plasma cutters produce a very hot and very localized "cone" to cut with, they are extremely useful for cutting sheet metal in curved or angled shapes.

Plasma cutting grew out of plasma welding in the 1960s, and emerged as a very productive way to cut sheet metal and plate in the 1980s. It had the advantages over traditional "metal against metal" cutting of producing no metal chips, giving accurate cuts, and producing a cleaner edge than oxy-fuel cutting. Early plasma cutters were large, somewhat slow and expensive and, therefore, tended to be dedicated to repeating cutting patterns in a "mass production" mode.

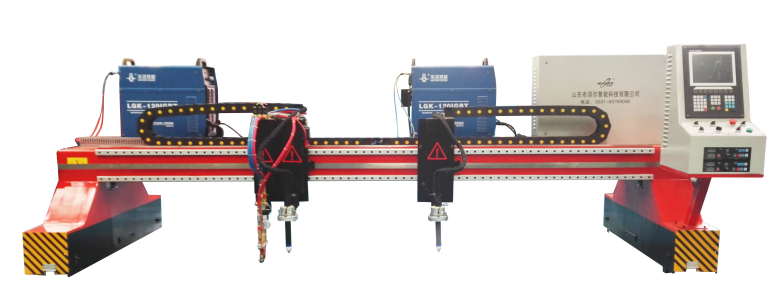

As with other machine tools, CNC (computer numerical control) technology was applied to plasma cutting machines in the late 1980s into the 1990s, giving plasma cutting machines greater flexibility to cut diverse shapes "on demand" based on a set of instructions that were programmed into the machine's numerical control. These CNC plasma cutting machines were, however, generally limited to cutting patterns and parts in flat sheets of steel, using only two axes of motion (referred to as X Y cutting).